commercial appliances didn’t take any stand-by measures to avoid “keeping the wires warm”

Generally speaking, the amount of standby current attributable to the capacitors has historically paled in comparison to the much higher standby current of the active electronics therein. The One Watt Initiative is one such program that shed light on "vampire draw" and posed a tangible target for what standby power draw for an appliance should look like: 1 Watt.

A rather infamous example of profligate standby power was TV set-top boxes, rented from the satellite or cable TV company, at some 35 Watts. Because these weren't owned by customers, so-called free-market principles couldn't apply and consumers couldn't "vote with their feet" for less power-hungry set-top boxes. And the satellite/cable TV companies didn't care, since they weren't the ones paying for the electricity to keep those boxes powered. Hence, a perverse scenario where power was being actively wasted.

It took both carrots (eg EnergyStar labels) and sticks (eg EU and California legislation) to make changes to this sordid situation. But to answer your question in the modern day, where standby current mostly is now kept around 1 Watt or lower, it all boils down to design tradeoffs.

For most consumer products, a physical power-switch has gone the way of the dodo. The demand is for products which can turn "off" but can start up again at a moment's notice. Excellent electronics design could achieve low-power consumption in the milliwatts, but this often entails an entirely separate circuit and supply which is used to wake up the main circuit of the appliance. That's extra parts and thus more that can go wrong and cause warranty claims. This is really only pursued if power consumption is paramount, such as for battery-powered devices. And even with all that effort, the power draw will never be zero.

So instead, the more common approach is to reuse the existing supply and circuitry, but try to optimize it when not in active operation. That means accepting that the power supply circuitry will have some amount of always-on draw, and that the total appliance will have a standby power draw which is deemed acceptable.

I would also be remiss if I didn't mention the EU Directives since 2013 which mandate particular power-factor targets, which for most non-motor appliances can only be achieved with active components, ie Active Power Factor Correction (Active PFC). While not strictly addressing standby power, this would be an example of a measure undertaken to avoid the heating caused by apparent power, both locally and through the grid.

Walgreens: free 8x10 print. Use code FREE4U . Exp 3 October

Save on photo prints and enlargements. Print and enlarge your photos at Walgreens Photo with easy editing and same-day in-store pickup.

Use the code on the Walgreens app and the website to claim the same offer twice!

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

How were you measuring the current in the power cable? Is this with a Kill-o-watt device or perhaps with a clamp meter and a line splitter?

As for why there is a capacitor across the mains input, a switching DC power supply like an ATX PSU draws current in a fairly jagged fashion. So to stabilize the input voltage, as well as preventing the switching noise from propagating through the mains and radiating everywhere, some capacitors are placed across the AC lines. This is a large oversimplification, though, as the type and values of these capacitors are the subject of careful design.

Since a capacitor charges and discharges based on the voltage across it, and because AC power changes voltage "polarity" at 50 or 60 Hz, the flow of charge into and out of the capacitor will be measurable as a small current.

Your choice of measuring instrument will affect how precisely you can measure this apparent power, which will in-turn affect how your instrument reports the power factor. It can also be that the current in question also includes some of the standby current for keeping the PSU's logic ICs in a ready state, for when the computer starts up. So that would also explain why the power factor isn't exactly zero.

An outside description of Squatober: https://www.garagegymreviews.com/squatober

I like the concept of a month-long squat fitness challenge but I personally don't jive with the notion of having to follow two Instagram accounts daily to get the next day's program description. My life requires a bit more advance notice than that.

Agreed, it's a very bad design. If your school speed limit covers most of the daylight hours on weekdays, is the implicit suggestion that it's fine to drive faster on weekends and during nighttime? The street should be rebuilt to enforce the desired speed limits, not with paint or signs.

Oh, we're talking about the letters on the glass. My bad lol

You may want to include a photo of the piece, ideally many photos from various angles.

But to be frank, unless you find someone within a max 1 hour's travel distance, it's not likely someone will be found who is also willing to take on this project. Wood furniture is, for all its pros and cons, heavy.

A few months ago, my library gained a copy of Cybersecurity For Small Networks by Seth Enoka, published by No Starch Press in 2022. So I figured I'd have a look and see if it it included modern best-practices for networks.

It was alright, in that it's a decent how-to guide for a novice to set up sensible, minimum network fortifications. But it only includes an overview of how those fortifications work, without going into the additional depth needed to fine-tune or optimize them for specific environments. So if the reader has zero experience with network security, it's a worthwhile read. But if you've already been operating a network with defenses for a while, there's not much to gain from this particular text.

Also, the author suggests that IPv6 should be disabled, which is a terrible idea. Modern best-practice is not to pretend IPv6 doesn't exist, but to assure that firewalls and other defenses are configured to handle this traffic. There's a vast difference between "administratively reject IPv6 traffic in/out of the WAN" and "disable IPv6 on all devices and pray no one ever connects an IPv6-enabled device".

You might have a look at other books available from No Starch Press, though.

I lost it when coming across this commit: https://github.com/WinampDesktop/winamp/commit/67c68e6dc24f36b266427034d016fb86ef4d486c

Other commenters addressed some of the possible clearance issues, where a wider tire might interfere with the frame. But it seems to me that the discussion on tire/rim compatibility can be fleshed out.

To lay some background, a bicycle tire is essentially mostly a hollow rubber donut, but with the inward-facing "donut hole" walls supported instead by a pair of co-axial steel hoops, known as the beads. Thus, the beads define the inner diameter of the tire. When a tire is inflated, the air pressure will cause expansion in all directions. The tire's beads and walls (ie casing) will hold their shape, but the air pressure will try to push the two beads apart. This is where the rim walls come into play: the rim walls prevent the beads from widening apart. With the air pressure fully contained in all directions, the wheel assembly can now support impressive loads relative to the weight of the rubber and metal.

So for a bicycle rim and bicycle tire to be compatible, the two most basic criteria must be met:

- the tire's bead diameter must exactly match the rim's "seated" diameter, ie at the bottom of the rim walls

- the beads must fit within the rim walls, being neither too narrow or too wide, such that the tire maintains its correct shape and that normal loads will not cause the beads to slip out of the rim walls

The first criteria is a strict match, so that's easy to check. But the second criteria has some allowance for different tire widths on a given rim, or different rims for a given tire width. We can now look at what rims you have, and whether they're compatible with your preferred tires.

It looks like your rims are Weinmann DP18 rims, which have a trade diameter of 700C and the narrowest part of the rim walls are 12.40 mm apart. I say "trade diameter" because no part of the rim actually measures 700 mm. Instead, rim/tire compatibility can only reliably be calculated using the ISO/ETRTO measurements, which are a pair of numbers that directly answer the two compatibility criteria from earlier.

The first number in the ETRTO system is the inner rim width, and the second number is the bead seat diameter, both in millimeters. So your rims would be universally identified as 12-622 or 13-622, since 622 mm is the actual circumference if you put a tape measure around the rim. The first number can be 12 or 13 because 12.40 mm could round up or down. Sub-mm precision does not substantially matter here.

Now we can look at your desired tires, which have a trade designation of 700x38c but they also give the ETRTO measurement of 40-622. Unlike rims, the trade designation does actually convey some measurable dimension of the tire, but these are irrelevant for tire/rim compatibility. See the spoiler below for more.

fuller explanation of tire trade designations

In this case, 700 mm is the approximate outer diameter of the tire, which is only useful if:

- you're setting up your bike computer's speedometer (bigger diameter means more distance per wheel revolution)

- or you need to calculate the wheel's ground clearance or its clearance to the forks

Also, 38 mm is the approximate width of the tire when inflated. This is allowed to differ from the ETRTO width, since balloon tires on MTB bikes can be substantially wider than the rim, and road bike tires can be narrower than the rim. This width is mostly only useful to check the clearance between your forks, although it's also useful to know if you're riding near streetcar tracks.

Narrow tires can get caught in the groove along the tracks, whereas wider tires can glide over them. A skilled rider can navigate tracks with any tire width, but it's still a hazard that needs to be identified and negotiated.

So we now know the rim is 13-622 and the desired tire is 40-622. Checking the first criteria, we see that the diameters (622 mm) are a perfect match. Great! But for the width, because there is an allowable range, we need to consult a width compatibility table. Some tire manufacturers will be more permissive while others are more conservative with their published tables. And there are often separate tables for road bikes versus MTB. But these tables won't vary too substantially in their recommendations. Here are two tables, one from Continental and another from WTB.

Both tables indicate that for the 13 mm rim width column, the recommended tire widths are 18-27 mm (Continental) or 23-25 mm (WTB). Your preferred tire has an ETRTO width of 40 mm, which is way too far outside of the recommendations. So no, it doesn't look like this tire can be safely mounted on your existing rims.

But what would happen if you tried it anyway? We can see from the table that a 40 mm tire should normally be mounted on a rim with widths 17-27 mm. So 13 mm would mean the tire beads will be squeezed closer together than designed. This means more of the tire's tread will be wrapped up on the sides rather than facing down at the road. This also reduces the contact patch where the tire meets the road.

Finally, a wide tire on a narrow rim exerts more leverage that could pull the tire up and off the rim. This would happen if the bike is loaded sideways, such as leaning the bike to one side while riding straight, or when the rider leans further than the bike in a curve. The recommended values take these conditions into account, so exceeding the recommendations might still work day-to-day but fail during rarer conditions.

My recommendation is to pursue a new set of rims that can support tire widths suitable for your new environment. As the tables show, 13 mm rims are very limiting, but 17 mm rims are very permissive. Indeed, a 17 mm rim would actually allow you to mount your preferred tires (ETRTO 40-622) and possibly your existing tires (ETRTO 25-622 ?) too, if you wanted to.

I wish you good luck in your endeavors!

This reminds me of the time I happened to be at a warehouse where an industrial motor control panel was being decommissioned. In the center of the panel is a large breaker, which was dutifully opened (ie powered off) before work commenced. But bizarrely, someone in the past managed to tap power from the supply-side of the breaker for some sort of monitoring sensor inside the panel. So when that circuit was cut through, there was a loud bang and the overhead lights went out.

No one was injured, although everyone was jumpy from the inadvertent light-and-sound spectacle. And a set of cutters gained a 12 AWG-sized (approx 4 mm^2) hole.

I may have misremembered some details, but my takeaway as a non-electrician was to 1) never assume a breaker handle at face value, and 2) don't assume the prior person made sane choices.

This is a good question and I don't really know how this device would affect drafting and related manoeuvres. But if I had to guess, drafting behind a lead cyclist should still be beneficial, but the "zones" where it works might change.

So for example, the optimal distance lee-ward of a lead cyclist might become shorter or longer. Longer could mean more space to vie for that position directly behind the lead. But shorter might mean it's impossible to draft without crashing into the lead.

Side-to-side drafting distances might also be affected, like how birds travel in a vee-shape. Maybe the vee would become wider? That might not be beneficial, though, if it's so wide that it's impossible to stay on the racecourse.

TL;DR: I have no idea, and aerodynamics are hard. That's why I'm intrigued by the field.

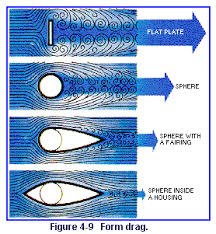

My understanding is that it has to do with form drag -- aka pressure drag -- which results in vortices forming in the "separation region" directly behind an airfoil. Or in this case, a rider. Essentially, the swirling of air behind the rider is turbulent -- which is why a hoodie might flop all over the place -- and that causes energy to be lost.

This video on Nebula (and YT as well) describes pressure drag at about the 02m30s mark for a sphere. But this graphic from Skybrary also shows the problem:

By providing a smooth surface for air to "cling" to, where it would otherwise form vortices in the separation region, should reduce form drag, although it will cause additional induced drag (aka friction with the new surface). But induced drag scales with speed and at cycling speeds, that's less a problem than it would be at airplane speeds.

A related drag-reducing device has been used for semi-truck trailers, and those have really been proven to reduce fuel consumption. Although the Wikipedia article does not describe in detail the aerodynamic principles at play.

For reference, the current Flag of Milwaukee, WI, which is quite busy:

As for the so-called "People's Flag" -- either with or without the city hall barreling into the harbor -- it bears a small resemblance to the flag of Reno, NV, which is a pleasing flag.

Robert Lenz’s “Sunrise Over the Lake”, selected after a public competition, which prompted the humorous version with the city hall building.

The thing to keep in mind is that there exist things which have "circumstantial value", meaning that the usefulness of something depends on the beholder's circumstances at some point in time. Such an object can actually have multiple valuations, as compared to goods (which have a single, calculable market value) or sentimental objects ("priceless" to their owner).

To use an easy example, consider a sportsball ticket. Presenting it at the ballfield is redeemable for a seat to watch the game at the time and place written on the ticket. And it can be transferred -- despite Ticketmaster's best efforts -- so someone else could enjoy the same. But if the ticket is unused and the game is over, then the ticket is now worthless. Or if the ticket holder doesn't enjoy watching sportsball, their valuation of the ticket is near nil.

So to start, the coupon book is arguable "worth" $30, $0, or somewhere in between. Not everyone will use every coupon in the book. But if using just one coupon will result in a savings of at least $1, then perhaps the holder would see net-value from that deal. In no circumstance is KFC marking down $30 on their books because they issued coupons that somehow total to $30.

That said, I'm of the opinion that if a donation directly results in me receiving something in return... that's not a donation. It's a sale or transaction dressed in the clothes of charity. Plus, KFC sends coupons in the mail for free anyway.

Notwithstanding the possible typo in the title, I think the question is why USA employers would prefer to offer a pension over a 401k, or vice-versa.

For reference, a pension is also known as a defined benefit plan, since an individual has paid into the plan for the minimum amount will be entitled to some known amount of benefit, usually in the form of a fixed stipend for the remainder of their life, and sometimes also health insurance coverage. USA's Social Security system is also sometimes called the public pension, because it does in-fact pay a stipend in old age and requires a certain amount of payments into the fund during one's working years.

Whereas a 401k is uncreatively named after the tax code section which authorized its existence, initially being a deferred compensation mechanism -- aka a way to spread one's income over more time, to reduce the personal taxes owed in a given year -- and then grew into the tax-advantaged defined contribution plan that it is today. That is, it is a vessel for saving money, encouraged by tax advantages and by employer contributions, if any.

The superficial view is that 401k plans overtook pensions because companies wouldn't have to contribute much (or anything at all), shifting retirement costs entirely onto workers. But this is ahistorical since initial 401k plans offered extremely generous employer contribution rates, some approaching 15% matching. Of course, the reasoning then was that the tax savings for the company would exceed that, and so it was a way to increase compensation for top talent. In the 80s and 90s was when the 401k was only just taking hold as a fringe benefit, so you had to have a fairly cushy job to have access to a 401k plan.

Another popular viewpoint is that workers prefer 401k plans because it's more easily inspectable than a massive pension fund, and history has shown how pension funds can be mismanaged into non-existence. This is somewhat true, if US States' teacher pension funds are any indication, although Ontario Teacher's Pension Plan would be the counterpoint. Also, the 401k plan participants at Enron would have something to complain about, as most of the workers funds were invested in the company itself, delivering a double whammy: no job, and no retirement fund.

So to answer the question directly, it is my opinion that the explosion of 401k plans and participants in such plans -- to the point that some US states are enacting automatic 401k plans for workers whose employers don't offer one -- is due to 1) momentum, since more and more employers keep offering them, 2) but more importantly, because brokers and exchanges love managing them.

This is the crux: only employers can legally operate a 401k plan for their employees to participate in. But unless the employer is already a stock trading platform, they are usually ill-equiped to set up an integrated platform that allows workers to choose from a menu of investments which meet the guidelines from the US DOL, plus all other manner of regulatory requirements. Instead, even the largest employers will partner with a financial services company who has expertise on offering a 401k plan, such as Vanguard, Fidelity, Merrill Edge, etc.

Naturally, they'll take a cut on every trade or somehow get compensated, but because of the volume of 401k investments -- most people auto-invest every paycheck -- even small percentages add up quickly. And so, just like the explosion of retail investment where ordinary people could try their hand at day-trading, it's no surprise that brokerages would want to extend their hand to the high volume business of operating 401k plans.

Whereas, how would they make money off a pension fund? Pension funds are multi-billion dollar funds, so they can afford their own brokers to directly buy a whole company in one-shot, with no repeat business.

Almost. By virtue of being a smaller antenna, the 30 cm panel does not focus its energy as tightly as a larger (eg 60 cm) antenna. Likewise, a smaller antenna does not pick up (ie receive) as much energy as a larger antenna does. Thus, by using a 30 cm panel, less of the high energy from the opposite radio will reach the receiver, and that keeps the receiver from being damaged.

In RF engineering, there is a careful balance between output power, antenna size/shape, environmental conditions, and desired link quality. Whoever built the radio link originally did not apparently perform the necessary calculation. I'm not an RF engineer, but for spanning a mere 50 meters, this 20 cm antenna with built-in radio should be more than sufficient for a basic link.

Normally, increased RF power is helpful to overcome interference or noise. Just like how normally, an automobile or airplane will be easier to operate if it has a bigger engine with more power.

At some point, though, the extra RF or engine power is no longer beneficial but also isn't harmful. And if you go significantly beyond that, then you end up in a region where the extra power is downright harmful and is actively working against you.

Consider an automobile driving in a rainstorm. Having more power is bad, because the tires can lose grip more easily, leading to a crash. In an airplane that has gotten into a stall, applying power is the wrong solution and just aggravates the stall, which is not good.

Here, adding more RF power is just cooking the other receiver like it's a Thanksgiving turkey. The extra power is no longer helpful for making communications, and may be physically damaging the receiver.

Although copyright and patents (and trademarks) are lumped together as "intellectual property", there's almost nothing which is broadly applicable to them all, and they might as well be considered separately. The only things I can think of -- and I'm not a lawyer of any kind -- are that: 1) IP protection is mentioned vaguely in the US Constitution, and 2) they all behave as property, in that they can be traded/reassigned. That's it.

With that out of the way, it's important to keep in mind that patent rights are probably the strongest in the family of IP, since there's no equivalent "fair use" (US) or "fair dealing" (UK) allowance that copyright has. A patent is almost like owning an idea, whereas copyright is akin to owning a certain rendition plus a derivative right.

Disney has leaned on copyright to carve for themselves an exclusive market of Disney characters, while also occasionally renewing their older characters (aka derivatives), so that's why they lobby for longer copyright terms.

Whereas there isn't really a singular behemoth company whose bread-and-butter business is to churn out patents. Inventing stuff is hard, and so the lack of such a major player means a lack of lobbying to extend patent terms.

To be clear, there are companies who rely almost entirely on patent law for their existence, just like Disney relies on copyright law. But type foundries (companies that make fonts) are just plainly different than Disney. Typefaces (aka fonts) as a design can be granted patents, and then the font files can be granted copyright. But this is a special case, I think.

The point is: no one's really clamoring for longer parents, and most people would regard a longer exclusive term on "ideas" to be very problematic. Esp if it meant pharmaceutical companies could engage in even more price-gouging, for example.

The original tech installed a 60cm panel for a rf link which is no more than 50M.

In case anyone else has this minor confusion, this is a radio link between two buildings which are 50 meters apart. And a square, directional flat-panel antenna that is 60 centimeters on a side is grossly overkill for the short distance involved.

To be clear, the legs would support the topper when it's positioned over the tub, and also support the topper when it's beside the tub? If that's the case, do the legs really need to fold away? Would fixed legs be acceptable? Or is there a requirement that the legs be foldable to provide clearance over the edge of the tub?

If you hold a patent, then you have an exclusive right to that invention for a fixed period, which would be 20 years from the filing date in the USA. That would mean Ford could not claim the same or a derivative invention, at least not for the parts which overlap with your patent. So yes, you could sit on your patent and do nothing until it expires, with some caveats.

But as a practical matter, the necessary background research, the application itself, and the defense of a patent just to sit on it would be very expensive, with no apparent revenue stream to pay for it. I haven't looked up what sort of patent Ford obtained (or maybe they've merely started the application) but patents are very long and technical, requiring whole teams of lawyers to draft properly.

For their patent to be valid, they must not overlap with an existing claim, as well as being novel and non-obvious, among other requirements. They would only file a patent to: 1) protect themselves from competition in future, 2) expect that this patent can be monetized by directly implementing it, or licensing it out to others, or becoming a patent troll and extracting nuisance-value settlements, or 3) because they're already so deep in the Intellectual Property land-grab that they must continue to participate by obtaining outlandish patents. The latter is a form of "publish or perish" and allows them to appear like they're on the cutting edge of innovation.

A patent can become invalidated if it is not sufficiently defended. This means that if no one even attempts to infringe, then your patent would be fine. But if someone does, then you must file suit or negotiate a license with them, or else they can challenge the validity of your patent. If they win, you'll lose your exclusive rights and they can implement the invention after all. This is not cheap, and Ford has deep pockets.

Walgreens: free 8x10 print. Use code FREEPICT . Exp 10 September

Save on photo prints and enlargements. Print and enlarge your photos at Walgreens Photo with easy editing and same-day in-store pickup.

Use the code on the Walgreens app and the website to claim the same offer twice!

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

Walgreens: free 8x10 print. Use code EIGHT-TEN . Exp 22 August

Save on photo prints and enlargements. Print and enlarge your photos at Walgreens Photo with easy editing and same-day in-store pickup.

Use the code on the Walgreens app and the website to claim the same offer twice!

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

CVS: 2x free 5x7 prints. Use code AUGFREE . Exp Unknown

You must have exactly two 5x7 glossy prints in your cart for the code to apply.

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

Survey of ebikes, escooter injuries: injured ages skew higher, not lower

This cross-sectional study examines the number of injuries and hospitalizations associated with electric vs conventional bicycles and scooters from 2017 to 2022.

> The median age of injured conventional bicycle riders was 30 (IQR, 13-53) years vs 39 (IQR, 25-55) years for e-bicyclists (P < .001). Scooter riders had a median age of 11 (IQR, 7-24) years at the time of injury vs 30 (IQR, 20-45) years for e-scooter riders (P < .001) (Table 1 and Figure 3). As a group, those injured from EV accidents were significantly older than those injured from conventional vehicles (age, 31 vs 27 years; P < .001) (eTable 1 in Supplement 1).

> e-Bicycles have lowered barriers to cycling for older adults, a group at risk for physical inactivity.9,10 Biking has clear-cut physical and cognitive health benefits for older adults, so this extension of biking accessibility to older e-bicyclists should be considered a boon of the new technology.22,23 However, as injured e-bicycle riders are older than conventional bicyclists, the unique safety considerations for older cyclists should be a focus of ongoing study.

There is a popular conception that ebikes are ridden recklessly on streets and sidewalks by youths, doing dangerous stunts, riding against traffic, not wearing helmets, and incurring serious injury to themselves and others as a result. This conception is often used to justify legislation to restrict or ban ebike use by minors. However, the data suggests quite the opposite, as it is older riders which are racking up injuries.

The data does not support restrictions on ebikes, but rather their wholesale adoption, especially for audiences which are at risk of inactivity or disadvantaged by a lack of transportation options. Ebikes are not at odds with conventional bicycles.

The California Bicycle Coalition offers this succinct summary:

> “We think this backlash against e-bikes is the wrong direction for what we want for safer ways for people biking and sharing the road,” said Jared Sanchez, the policy director for the California Bicycle Coalition. “We don’t believe that adding restrictions for people riding e-bikes is the solution.”

They also have a page on how to fight against "bikelash", aka naysayers of bicycles and bikes: https://www.calbike.org/talking-back-to-bikelash/

Walgreens: six free 5x7 photo cards. Use code SAMEDAY6 . Exp 16 August

Make your Design Catalog with photos displaying your favorite family moments. Design and create unique custom Design Catalog online.

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

Walgreens: free 8x10 print. Use code FREEPIC . Exp 9 August

Save on photo prints and enlargements. Print and enlarge your photos at Walgreens Photo with easy editing and same-day in-store pickup.

Use the code on the Walgreens app and the website to claim the same offer twice!

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

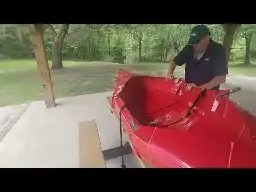

Tucktec Folding Kayak: Buy, Not Buy, or Other?

TUCKTEC 10' folding kayak provides excellent balance, minimizing the risk of tipping over, even for beginners. TUCKTEC Kayak is a ideal companion for your waterborne journeys.

I have no prior kayaking experience except occasionally paddling one while camping with friends on still water. That's fun and all, but I'd like to get out on the water on my own, to some of the nearby lakes near me, maybe once a month during the sunny seasons. None of these would have anything remotely considered as "rapids".

My main consideration is transporting a prospective kayak, as I greatly prefer biking rather than driving a car for distances within an hour of me, which includes two or three suitable bodies of water. While I have the capacity to store a conventional hard-shell kayak at home, I'm exploring a folding kayak, since this could go with me in a car for farther locations, on a bike for nearby waters, and even a bus. I feel the hassle of moving a 12 ft hard-shell kayak would discourage me from ever using it outright.

This specific model won't ship until October, which might be a bit late in the season, but it's on sale for $300 out the door, or $273 because of a 10% email coupon for keeping it in my cart for an hour.

I'm aware that this isn't anywhere comparable to conventional kayaks, certainly not in price, rough water handling, and maybe not even longevity. But at this particular juncture, and for that particular price point, I think I have a use-case that aligns well with a folding kayak, and if I do develop the itch for something even better, I can always upgrade later. I can accept that this might be a "kayak-shaped toy", but if it floats on water and moves, I would be happy to start with that.

To that end, my questions for this community are whether there are other comparable folding kayaks I should look at, or reasons I should or shouldn't proceed with this purchase in the coming days.

Any and all advice would be greatly appreciated!

Update: I've ordered it and hope to see how it turns out when it arrives in October

Walgreens: free 8x10 print. Use code DAYSFREE . Exp 26 July

Save on photo prints and enlargements. Print and enlarge your photos at Walgreens Photo with easy editing and same-day in-store pickup.

Use the code on the Walgreens app and the website to claim the same offer twice!

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

A wood seat made from scraped pallets

cross-posted from: https://sh.itjust.works/post/22165919

> This entry of mine will not match the customary craftsmanship found in this community, but seeing as this was formerly a pile of miscellaneous, warped scrap 2x4 segments recovered from old pallets, I think I've made a reasonable show of things. > > This bench is for my homegym, designed to be stood upon, which is why there's a rubber mat inlaid on the surface, a leftover of the gym floor. My design criteria called for even the edge of the top surface to support weight, so the main "box" of the bench uses 2x4 segments mitered (badly) together at 45 degrees, held together with wood glue. > > I then routed the inner edge to support a 1/2" plywood sheet, which is screwed into the box. And then the rubber mat is glued down to the sheet, so there are no visible screws. > > Finally, the legs are also 2x4 segments, cut so the bench sits 43 cm (~17 inch) from the floor; this is only coincidentally similar to the IPF weightlifting bench standards. I used screws instead of glue, just in case the legs needed to be shortened later. > > All edges were rounded over with a 1/2" bit, as the bench is expected to be picked up and moved frequently. And everything stained in cherry and clear-coated. > > Some of the annoyances from using scrap included: > * Stripping old paint off. Awful chemicals, awful scrubbing, awful disposal. > * Sanding away twists along the 2x4 segments > * Filling nail holes or arranging them so they don't draw attention > * My lack of experience with clamping and gluing wood that's not dimensionally consistent > > !wood bench beside a leg press > > If I were to do this again, I'd figure out a way to reduce the amount of routing needed for the inner edge, since I essentially removed 0.75 inch by 1.5 inch of material all around the edge. This took forever, and perhaps a CNC machine would have simplified things, in addition to squaring and planing the surfaces before mitering. > >

A wood bench made from scraped pallets

cross-posted from: https://sh.itjust.works/post/22165919

> This entry of mine will not match the customary craftsmanship found in this community, but seeing as this was formerly a pile of miscellaneous, warped scrap 2x4 segments recovered from old pallets, I think I've made a reasonable show of things. > > This bench is for my homegym, designed to be stood upon, which is why there's a rubber mat inlaid on the surface, a leftover of the gym floor. My design criteria called for even the edge of the top surface to support weight, so the main "box" of the bench uses 2x4 segments mitered (badly) together at 45 degrees, held together with wood glue. > > I then routed the inner edge to support a 1/2" plywood sheet, which is screwed into the box. And then the rubber mat is glued down to the sheet, so there are no visible screws. > > Finally, the legs are also 2x4 segments, cut so the bench sits 43 cm (~17 inch) from the floor; this is only coincidentally similar to the IPF weightlifting bench standards. I used screws instead of glue, just in case the legs needed to be shortened later. > > All edges were rounded over with a 1/2" bit, as the bench is expected to be picked up and moved frequently. And everything stained in cherry and clear-coated. > > Some of the annoyances from using scrap included: > * Stripping old paint off. Awful chemicals, awful scrubbing, awful disposal. > * Sanding away twists along the 2x4 segments > * Filling nail holes or arranging them so they don't draw attention > * My lack of experience with clamping and gluing wood that's not dimensionally consistent > > !wood bench beside a leg press > > If I were to do this again, I'd figure out a way to reduce the amount of routing needed for the inner edge, since I essentially removed 0.75 inch by 1.5 inch of material all around the edge. This took forever, and perhaps a CNC machine would have simplified things, in addition to squaring and planing the surfaces before mitering. > >

A wood bench made from scraped pallets

This entry of mine will not match the customary craftsmanship found in this community, but seeing as this was formerly a pile of miscellaneous, warped scrap 2x4 segments recovered from old pallets, I think I've made a reasonable show of things.

This bench is for my homegym, designed to be stood upon, which is why there's a rubber mat inlaid on the surface, a leftover of the gym floor. My design criteria called for even the edge of the top surface to support weight, so the main "box" of the bench uses 2x4 segments mitered (badly) together at 45 degrees, held together with wood glue.

I then routed the inner edge to support a 1/2" plywood sheet, which is screwed into the box. And then the rubber mat is glued down to the sheet, so there are no visible screws.

Finally, the legs are also 2x4 segments, cut so the bench sits 43 cm (~17 inch) from the floor; this is only coincidentally similar to the IPF weightlifting bench standards. I used screws instead of glue, just in case the legs needed to be shortened later.

All edges were rounded over with a 1/2" bit, as the bench is expected to be picked up and moved frequently. And everything stained in cherry and clear-coated.

Some of the annoyances from using scrap included:

- Stripping old paint off. Awful chemicals, awful scrubbing, awful disposal.

- Sanding away twists along the 2x4 segments

- Filling nail holes or arranging them so they don't draw attention

- My lack of experience with clamping and gluing wood that's not dimensionally consistent

!wood bench beside a leg press

If I were to do this again, I'd figure out a way to reduce the amount of routing needed for the inner edge, since I essentially removed 0.75 inch by 1.5 inch of material all around the edge. This took forever, and perhaps a CNC machine would have simplified things, in addition to squaring and planing the surfaces before mitering.

CVS: free 8x10 prints. Use code 810JULY . Exp Unknown

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

Leg press/hack squat/preacher curl bench

The idea for this strange combination of arm day and leg day came from realizing that my existing leg press and many commercial preacher curl benches both share a 45 degree angle. So in the interest of consolidating floor space, I decided to build a preacher curl bench attachment for my Force USA machine.

Just like with stripping down the machine to fit against a wall, the goal is to build something which is removable, if I wanted to restore the machine back to factory condition. Conveniently, at the top end of the machine, there are three 11/16 inch (17 mm) holes on each side, meant for resistance band pegs. Likewise, between the frame and the chrome running surface is approximately 1.5" (38 mm).

Thus, it made the most sense to cut pieces of 2x4 lumber (actual size: 1.5x3.5 inch) that will sit within the frame, secured by two snug-fitting 5/8 inch (16 mm) wood dowels going through the top-most band peg holes. These side-pieces are held captive by the dowels, although the pieces can still slide inward of the frame, falling away from the peg holes. They're also not really weight-bearing. But they do provide a foundation to build upon.

To form a sturdy and flat base, I then cut some scrap 3/4 inch (19 mm) board that spans the width of the frame, and screwed it down onto the side-pieces using Torx deck screws, notched to avoid protrusions on the frame's top surface. This makes the board weight-bearing, since it rests flat upon the frame; the side-pieces prevent the board from sliding down. And by fixing the width of the side-pieces, the pieces can no longer fall away from the peg holes.

!close up of preacher curl attachment on the leg press

Finally, any preacher curl bench requires a pad. For this, I simply went online and found what existing machines used. Having had a good experience with the parts department at Body Solid for my functional trainer, I looked at their GPCA1 preacher curl station, whose detailed PDF schematics showed a pad that is 600 mm wide, which is perfect for my use!

After $40 + $20 shipping, the pad arrived and I was able to measure the exact distance between its two bottom mounting holes to drill through the board. Once again, Body Solid's documentation described the exact 5/16" wide, 1" long bolts that I would need to mount the pad.

The final result isn't my nicest wood project -- to the point that I just stained it (badly) in black -- but it may have been one of the cheapest so far, using nearly entirely scrap materials except for the pad itself and the bolts. It also wasn't terribly complex and didn't require fairly high precision, unlike the short barbell project.

The whole premise of this attachment is that as an average height American (5 ft 9 inch; 175 cm), my range of motion for the leg press and hack squat simply won't ever push the carriage into the upper part of the frame. So it's free real estate.

!preacher curl pad attached to the top of a 45 degree leg press

But wait: how am I going to use this? The pad is 5.5 ft (167 cm) above the floor. I'd have to be over 7 ft tall (2.2 m) to drape my arms over it. The answer to that will be its own future post.

CVS: free 8x10 prints. Use code FREE108 . Exp 19 June

This is different than the promo from two days ago.

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

Making an 80 cm (31.5 inch) dumbbell from a Titan 15-inch adjustable dumbbell

cross-posted from: https://sh.itjust.works/post/20965205

> This is the story of how I turned a 15" Titan adjustable dumbbell to be 80 cm (31.5 inch) long. Why? Because I have a space-constrained home gym but still wanted a leg press, and so I had to remove its original barbell. > > In its place, I built a pair of wood mounts for a normal barbell to rest upon, covered in that earlier post. However, since this machine is wall-adjacent, such a barbell would have to fit inside the width of the leg press, so about 80 cm. But must also be wider than the spacing from outside-edge to outside-edge of the wood mounts, which is 60 cm. > > !wooden mounts where a leg press barbell would be > > Such a short barbell -- or long dumbbell -- does not readily exist commercially, with the narrowest one I've seen being 48 inch barbells, which are still too wide. So I decided to build my own, using my spare Titan dumbbell as the base. > > To start, the Titan dumbbells are excellent in this capacity, as the shaft diameter is 28 mm -- not 32 mm as the website would indicate -- which is a common diameter, if I am to cut short a cheap barbell to replace this dumbbell's shaft. > > In keeping with my preexisting frugality, I purchased a cheap 1-inch barbell, hoping that it adopts the Olympic 28 mm shaft diameter, and not the 29 mm deadlift bar shaft diameter, as the Titan collars have small clearances. Matching neither, I find that this bar is closer to 23 mm, which although will fit into the existing collars, poses its own issues. > > Nevertheless, this 7 ft barbell can conveniently be cut in half to yield two 42 inch segments. And then the included bar stops can be loped off, and then the length further refined to 77 cm, thus hiding the marks from the bar stop within the Titan collars, and also centering the (meh) knurling from the cheap bar. > > But perhaps a picture will be more explanatory. Here, the original collar is dismantled at the top, showing the original shaft with a groove cut into it, about 1/4-inch from the end. Into that groove would fit two half-rings with an inner diameter of 20.4 mm and an outer diameter of 40 mm. In fact, all the parts inside the collar use 40 mm outer diameter, except the spacer cylinder, which is smaller at 37 mm. All of these parts are held captive within the collar using the C-ring and the geometry of the collar itself. > > ! > > To deal with the difference between the collar expecting 28 mm, and the cheap bar's 23 cm, I designed an ABS 3d printed part in FreeCAD to act as a bushing, upon which the original Titan brass bushing will ride upon. This ABS bushing is held captive by way of its center bulge, which fits within the dead space inside the collar. > > ! > > As for how I cut the groove into the end of the new shaft, I still don't own a lathe. So the next best is to mount an angle grinder onto a "cross slide vise" taken from a drill press, with the shaft secured in a wooden jig to only allow axial rotation manually. The vise allows precision control for the cutting wheel's depth, with me pausing frequently to measure how close the groove is to the desired 20.4 mm inner diameter. This is.... not a quick nor precise process. But it definitely works. > > ! > > After reassembling both collars onto the new shaft and lubricating with white lithium, the final result is a long dumbbell (or short barbell) with Titan's 3.5 inch collars on the end, with 63 cm of shaft exposed and 80 cm from end to end. The ABS bushing is remarkably smooth against the brass bushing, after some sanding with 180 grit. The whole dumbbell weights 5.48 kg empty. > > ! > > Here is the comparison with the stock Titan dumbbell. It's pretty amazing how the knurling conveniently lined up. It fits well onto the wood mounts of the leg press. > > !Don't ever talk to me or my son ever again > ! > > But why would I do all this just to add a weirdly long 3.5-inch collar dumbbell to a leg press, when it already can accept weights underneath the carriage? I will answer that in a follow-up post.

Making an 80 cm (31.5 inch) dumbbell from a Titan 15-inch adjustable dumbbell

This is the story of how I turned a 15" Titan adjustable dumbbell to be 80 cm (31.5 inch) long. Why? Because I have a space-constrained home gym but still wanted a leg press, and so I had to remove its original barbell.

In its place, I built a pair of wood mounts for a normal barbell to rest upon, covered in that earlier post. However, since this machine is wall-adjacent, such a barbell would have to fit inside the width of the leg press, so about 80 cm. But must also be wider than the spacing from outside-edge to outside-edge of the wood mounts, which is 60 cm.

!wooden mounts where a leg press barbell would be

Such a short barbell -- or long dumbbell -- does not readily exist commercially, with the narrowest one I've seen being 48 inch barbells, which are still too wide. So I decided to build my own, using my spare Titan dumbbell as the base.

To start, the Titan dumbbells are excellent in this capacity, as the shaft diameter is 28 mm -- not 32 mm as the website would indicate -- which is a common diameter, if I am to cut short a cheap barbell to replace this dumbbell's shaft.

In keeping with my preexisting frugality, I purchased a cheap 1-inch barbell, hoping that it adopts the Olympic 28 mm shaft diameter, and not the 29 mm deadlift bar shaft diameter, as the Titan collars have small clearances. Matching neither, I find that this bar is closer to 23 mm, which although will fit into the existing collars, poses its own issues.

Nevertheless, this 7 ft barbell can conveniently be cut in half to yield two 42 inch segments. And then the included bar stops can be loped off, and then the length further refined to 77 cm, thus hiding the marks from the bar stop within the Titan collars, and also centering the (meh) knurling from the cheap bar.

But perhaps a picture will be more explanatory. Here, the original collar is dismantled at the top, showing the original shaft with a groove cut into it, about 1/4-inch from the end. Into that groove would fit two half-rings with an inner diameter of 20.4 mm and an outer diameter of 40 mm. In fact, all the parts inside the collar use 40 mm outer diameter, except the spacer cylinder, which is smaller at 37 mm. All of these parts are held captive within the collar using the C-ring and the geometry of the collar itself.

To deal with the difference between the collar expecting 28 mm, and the cheap bar's 23 cm, I designed an ABS 3d printed part in FreeCAD to act as a bushing, upon which the original Titan brass bushing will ride upon. This ABS bushing is held captive by way of its center bulge, which fits within the dead space inside the collar.

As for how I cut the groove into the end of the new shaft, I still don't own a lathe. So the next best is to mount an angle grinder onto a "cross slide vise" taken from a drill press, with the shaft secured in a wooden jig to only allow axial rotation manually. The vise allows precision control for the cutting wheel's depth, with me pausing frequently to measure how close the groove is to the desired 20.4 mm inner diameter. This is.... not a quick nor precise process. But it definitely works.

After reassembling both collars onto the new shaft and lubricating with white lithium, the final result is a long dumbbell (or short barbell) with Titan's 3.5 inch collars on the end, with 63 cm of shaft exposed and 80 cm from end to end. The ABS bushing is remarkably smooth against the brass bushing, after some sanding with 180 grit. The whole dumbbell weights 5.48 kg empty.

Here is the comparison with the stock Titan dumbbell. It's pretty amazing how the knurling conveniently lined up. It fits well onto the wood mounts of the leg press.

!Don't ever talk to me or my son ever again !

But why would I do all this just to add a weirdly long 3.5-inch collar dumbbell to a leg press, when it already can accept weights underneath the carriage? I will answer that in a follow-up post.

CVS: free 8x10 prints. Use code GIFT108 . Exp 19 June

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

Walgreens: free 8x10 print. Use code TYDAD . Exp 16 June

Save on photo prints and enlargements. Print and enlarge your photos at Walgreens Photo with easy editing and same-day in-store pickup.

Use the code on the Walgreens app and the website to claim the same offer twice!

When uploading photos using the desktop website, make sure to select Full Resolution in the Upload Preferences.

$1000 Honda Suitcase - Motocompacto Review

YouTube Video

Click to view this content.

As is their custom, FortNine delivers a two-wheeler review in the most cinematic way possible, along with a dose of British sitcom humor.

I'm not sure I'd ever buy one, but I'd definitely borrow it from a friend haha. I've said before that I like seeing what novel ideas people will build atop two wheels, and this certainly is very unique.