Search

Help wanted

Update: TL;DR: I cleaned the z-axis, replaced the nofep, installed the latest Chitubox (2.1) and cleaned up my profile to get it working

Hello, I hope someone will see this and be able to at least point me in the tight direction. As at this point I’m becoming desperate.

My Epax E10 4k is acting up, and I do not know why.

Part of the print is fine (see images) and then other parts are just stopped at a certain layer, with the rest stuck to the noFep.

I tried different prints, to make sure it wasn’t a layering problem, but alas… each single print suffered from the issue. The larger prints would ‘hang’ over non-printed layers…

I recalibrated my printer, changed the fep…

The one difference from before is the resin. I used to buy epax hard and tough, but my regular resin dealer doesn’t sell them anymore, heck it seems it is no longer available in europe. So I switched to the next best thing on the Epax compatibility list: eSun hard and tough.

Anybody have any clever idea?

Trouble with ASA prints

[SOLVED] cause: not enough cooling for overhangs

I increased cooling on overhangs from 60% to 100%, and decreased overhang (10-25%) speed from 100% of outer wall speed to 85%. Issue went away completely and it now prints nicely 👌

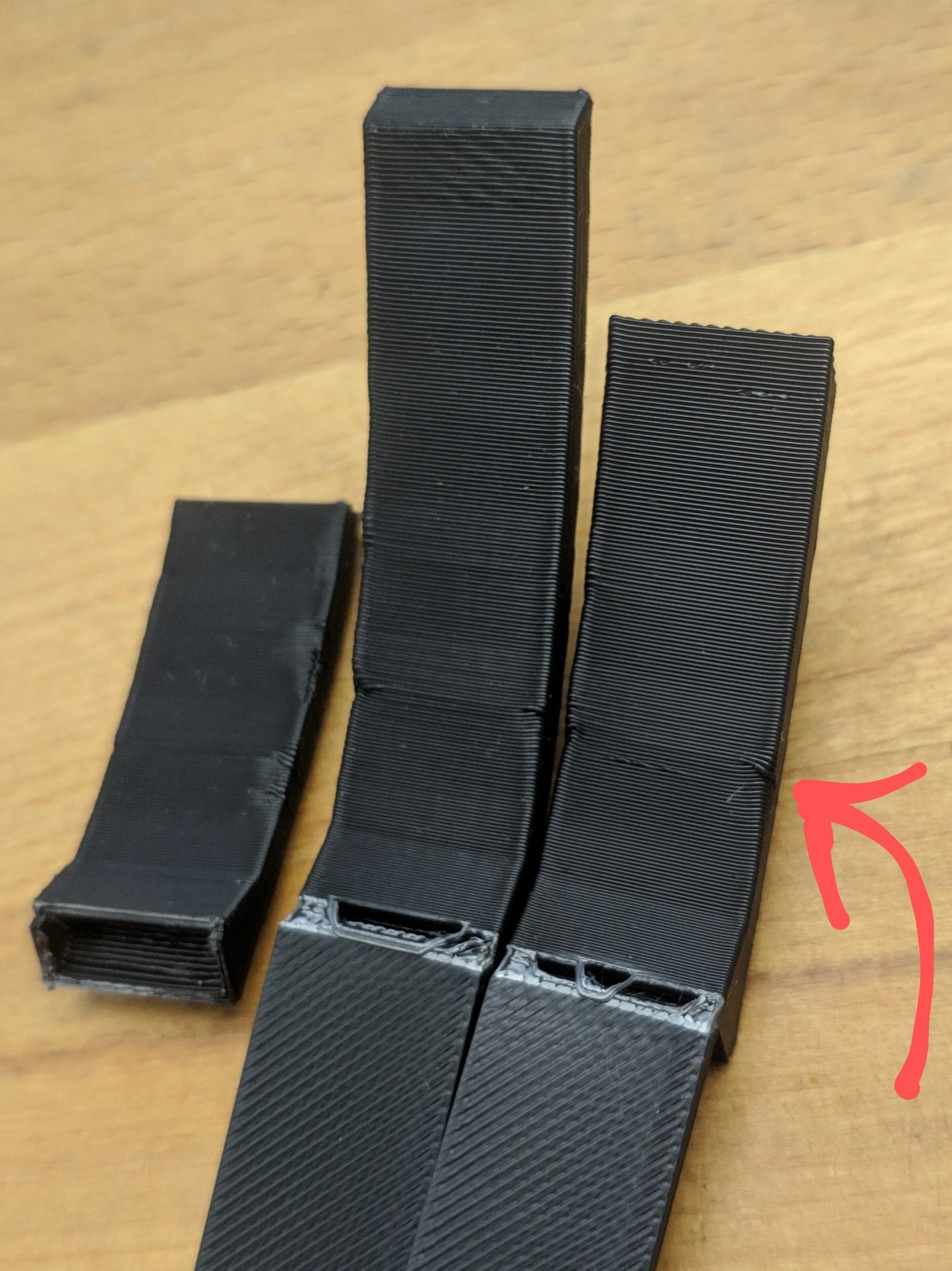

I've started printing parts for my voron 2.4, and it's generally going well enough. The parts are looking pretty decent. But I'm having a hard time getting good results with overhanging sharp corners. They tend to warp upwards as seen in the photo on the left side. The prints stick well enough to the build plate and I don't have any other warping or adhesion issues.

Is this because my cooling for overhangs is too much?

I generally print with no part cooling in an enclosure. Temps are 245°C on the nozzle and 105°C on the bed, using 60° fan speed for overhangs. I'm printing on a anycubic kobra 2 with azurefilm ASA.

Any ideas what causes this in overhangs?

When I do an overhang test, I always have this problem at about 35°. Does anyone have a suggestion what could be causing it?

- Slicer: Orca

- Layer height: 0.2mm

- Infill: 0% (this has improved it a lot, I think the infill was causing bulging)

- Outer walls: 2

- Overhang speed: 10 or 20mm/s (both look the same)

Solution: I mistakenly thought overhang speed in Orca was based on overhang angle, it is percentage instead (which makes much more sense for different layer heights). My 10-25% overhang speed wasn't set to slow down and that must translate to about 35° at 0.2mm layer height. I now have it set to 30mm/s and it now looks great 👍 And sorry, I was wrong when I stated the overhang speed 😅

Elegoo Neptune Pro 4 - Failed Print Help

I just sent this email over to elegoo official, so either way I'll update this post with their response for a community reference point:

"Hello, I'm having issues with my Elegoo Neptune Pro 4. I've tried following the official documentation and other resources to help fix my issue to no avail, so I am reaching out as a last ditch effort.

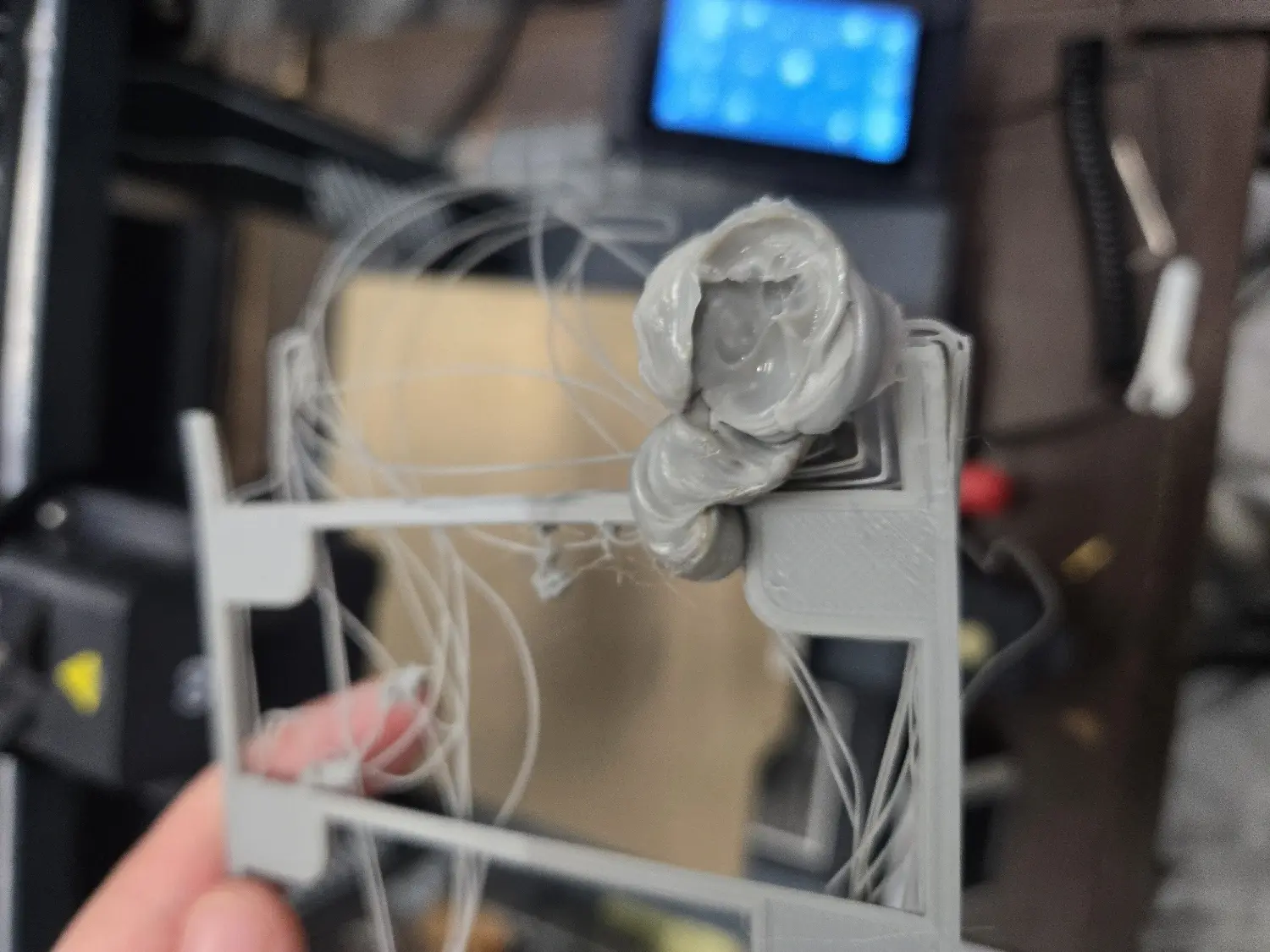

My issue mainly pertains to PLA prints consistently being ruined partway during printing after a few months of use and operation.

Specifically, my print will successfully complete the first few layers. Then, at some point, the print will somehow 'grab' or 'catch' the print base and drag it around the print bed, ruining the print and causing a large build up of filament at my hotend. This then requires cleaning.

From what I have seen, this can be caused by issues with the print bed not being clean or the temperature of the bed in relation to the fan speed. For example, having a low fan utilization at the beginning, then ramping up later in the print is supposed to help this issue. However any fixes I tried returned null results.

Some background info, I purchased the printer on preorder and received it in September 2023. I have kept up with maintenance. Namely, keeping stepper motor tracks cleaned and greased properly, belts tightened, the print bed is wiped down with 90% ISO alcohol between prints. I have replaced the hot-end when I first started experiencing print issues, and again during the troubleshooting process to further diagnose the problem. My Z offset seemingly is "correct". I followed the mfg instructions closely, and before this issue, my prints were coming out beautifully.

Print Settings: Using Elegoo brand PLA 1kg filament rolls. Default Elegoo Cura print settings applied for temperature, speed, fan speed, nozzle size, etc. Supports or No supports didn't make a difference during my troubleshooting. Brim printing mode is my default.

For the 4-5 months that I've had the Neptune Pro 4 has been absolutely amazing. Fantastic quality, consistent, very easy to use and maintain. The issues I'm experiencing are beyond annoying and I can't seem to figure it out myself.

Is this issue known? What are the recommended solutions?"

- Let me know if any of you have experienced something similar to this and how you addressed it!

EDIT: This is likely solved. There are many issues that can contribute to this issue but TLDR quadrouple check your z offsets. Read the thread for other good info.

Follow-up: Upgrading from Cura 4.12 to 5.6 no longer heats extruders or bed

Hi folks, this is a follow-up to my previous post here.

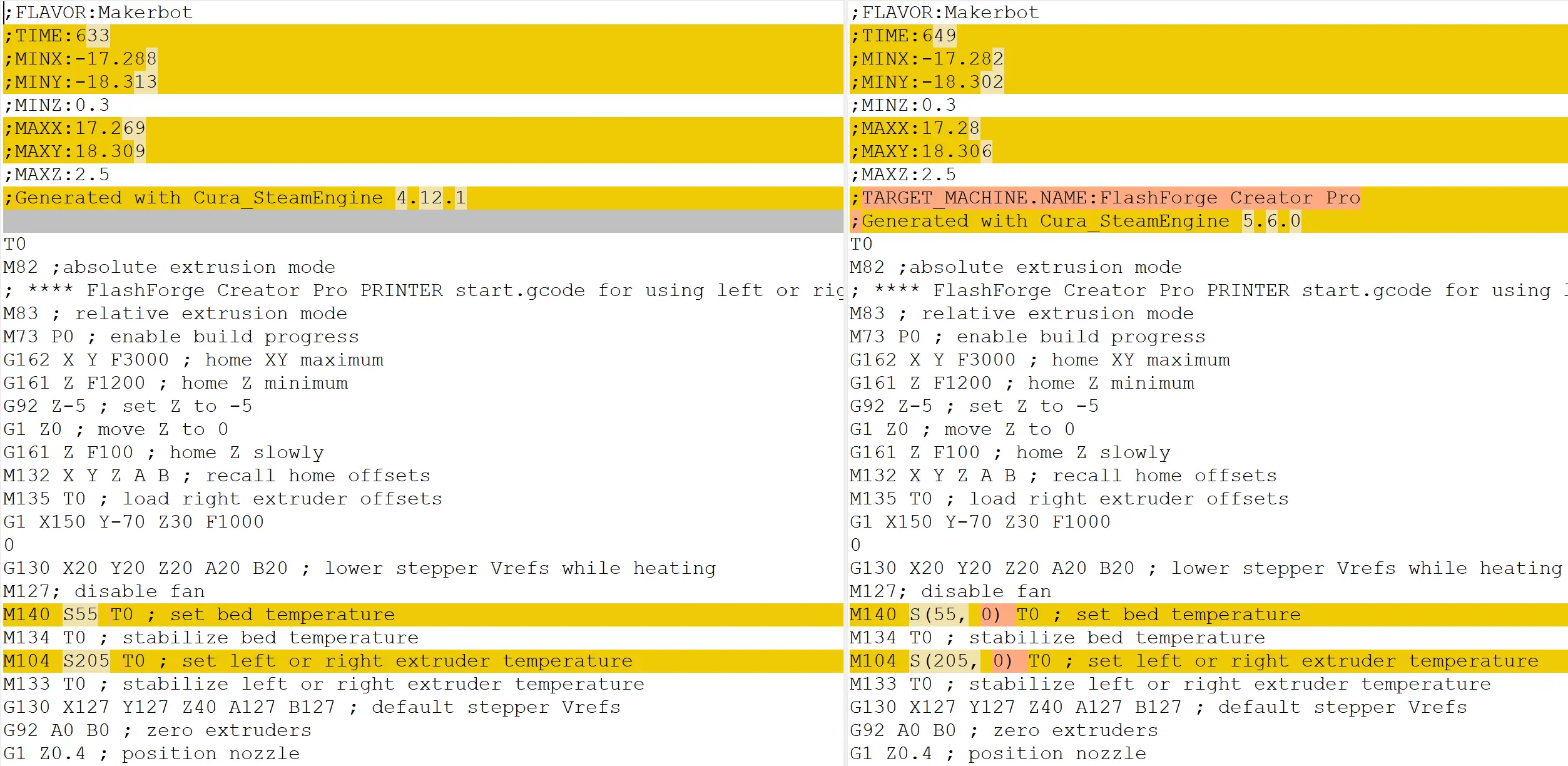

To briefly summarize, when upgrading Cura from 4.12 to 5.6, my printer and slicing profiles seemed to transfer over automatically, but when I tried to slice and print, I encountered a strange issue: It no longer heats the extruders or the bed. It just starts "printing" immediately with stone-cold extruders and bed.

Thanks to some suggestions under that post, I've narrowed down the problem to a couple of lines of in the start gcode (located in Settings > Printer > Manage Printers... > Machine Settings).

Cura start gcode:

M140 S{material_bed_temperature, initial_extruder_nr} T0 ; set bed temperature M134 T0 ; stabilize bed temperature M104 S{material_print_temperature_layer_0, initial_extruder_nr} T{initial_extruder_nr} ; set left or right extruder temperature M133 T{initial_extruder_nr} ; stabilize left or right extruder temperature

While the start gcode is identical between 4.12 and 5.6, it seems to be written differently in the output file.

Cura 4.12 output gcode file:

M140 S55 T0 ; set bed temperature M134 T0 ; stabilize bed temperature M104 S205 T0 ; set left or right extruder temperature M133 T0 ; stabilize left or right extruder temperature

Cura 5.6 output gcode file:

M140 S(55, 0) T0 ; set bed temperature M134 T0 ; stabilize bed temperature M104 S(205, 0) T0 ; set left or right extruder temperature M133 T0 ; stabilize left or right extruder temperature

I think I've identified the problem, but don't fully understand the reason. Cura 5.6 seems to copy both the temperature and initial_extruder_nr values, and places them in parentheses.

Could this discrepancy be the cause of the bed and extruders not heating?

What is initial_extruder_nr, and what does it do?

According to the fieldofview Replacement Patterns site, it is "the first extruder train used for the print". This doesn't sound like it is related to bed temperature.

Can I delete them from the temperature lines in the start gcode, or could this cause other issues?

Thanks in advance!

Edit: Whoops, this is embarrassing.

I just realized that sawecw commented two months ago on my original post and came to similar conclusions. I'll try Cura 5.7.

Edit 2:

I have upgraded to Cura 5.7, and can confirm that this bug has been fixed.

Stuttering when printing PETG

I tried printing with PETG yesterday, and I noticed that it intermittently stops moving during the print for a few seconds. It doesn't throw an error or anything, just stops and then after a few seconds resumes as if nothing happened. But this creates huge blobs where it stops. It only happens when printing PETG, not PLA. Could this be caused by a filament setting in my slicer? I'm using prusa slicer. I inspected the gcode and there are no stops, pauses or color changes etc. in it. The behaviour happens both when printing from octoprint and directly from SD card.

Edit: these random intermittent stops are 10-20 seconds long, causing massive blobs from oozing filament.

Edit 2: so it seems to not actually be a PETG specific issue, but rather a model size/speed issue. I can get it running without stops if I just reduce print speed. When I crank speed to 100% I start getting these weird 10-20 second long stops.

So I'm overloading the controller with a lot of gcode commands in rapid succession? I'm running at slightly lower than manufacturer default Max.

SOLVED: the gcode resolution was set too fine, I increased it from 0.0125mm to 0.5mm as described here and the stuttering disappeared.

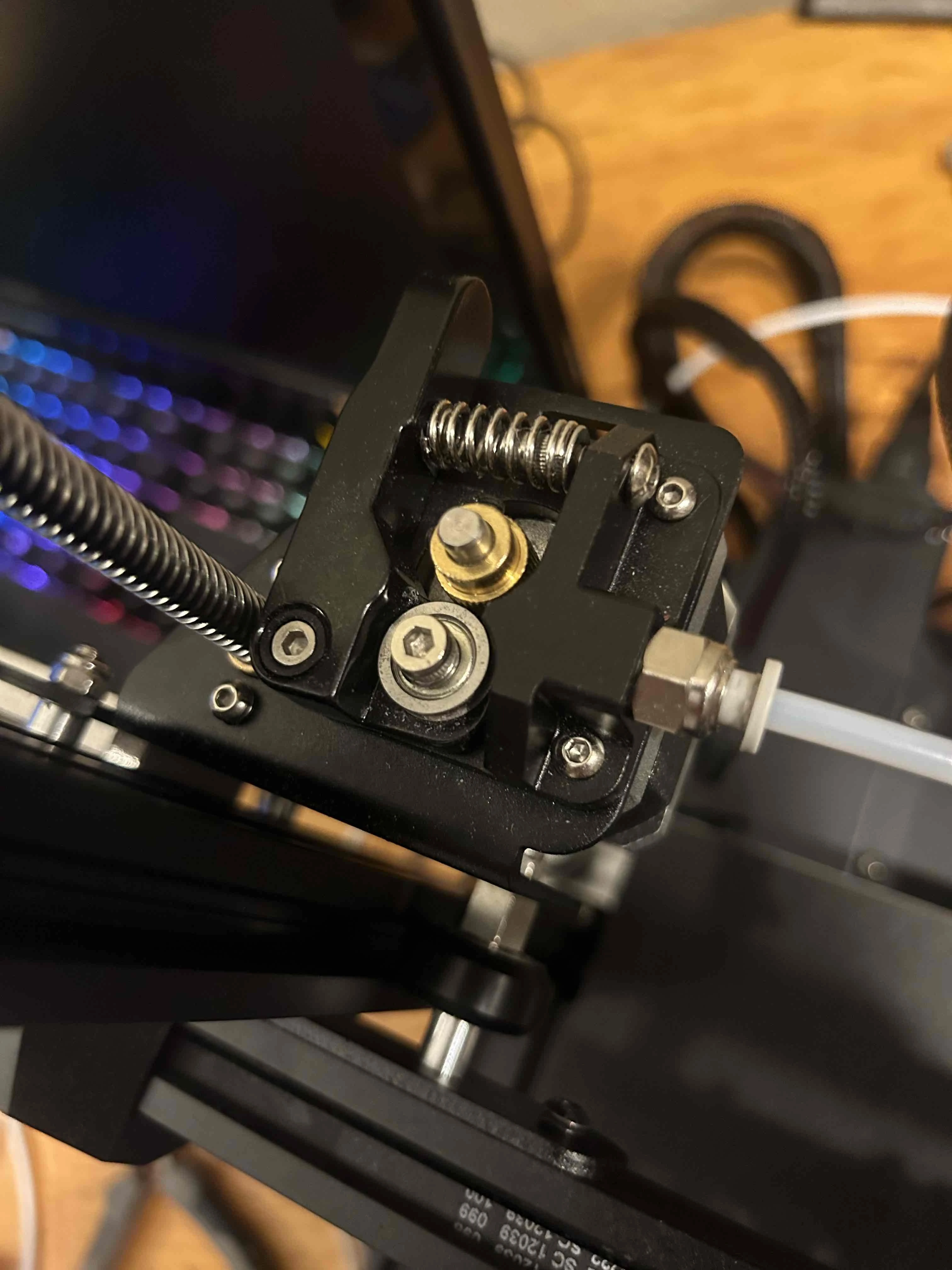

Extruder clicking

Is there any reason that little silver part of the extruder wouldn’t move and start clicking while printing when printing at 205 in PLA. It seems to turn just fine without any filament in there otherwise.

I cleaned out a nozzle clog, but is it possible there’s junk in the hot end stuck?

Resolution: Thanks for your help everyone! It ended up being a nozzle clog that I didn’t get all the way out. I ended up heating the printer up and doing the cool down trick. That seemed to work as a last ditch effort before buying a new nozzle.

My Print won't stick to the Bed

Thank you all for your help! After yesterday's Input I managed to Print my Box! The Problem was (mostly) the Bed temperature! The lower Bed temperature (60°C) and the now successful Firmware-Update (special thanks to DABDA) done the trick!

Thank you all for your help and your advice!

Hello I'm very new to 3D printing, I'm using a Sovol 06 with 1.75mm PLA. I'm trying to print a Box (for MTG-Cards). But everytime the bottom of the Box starts to "deatche" itself from the Bed. It starts with one corner and then progresses to the whole print. The Nozzle temperature is 200°C and the Bed temperature is 80°C. Can someone help?

Unable to print TPU 93A

EDIT: solution is in the comments. TL;Dr retractions ON and INCREASE speed. Both opposite to common knowledge.

I can't print flexible TPU properly. It's either foamy, inconsistent extrusion or jam city, nothing else. I wasn't able to complete a single print properly in a week and probably 50 tries.

Tried

- 24 hours of active drying

- speeds of 10-30mm/s

- flow rate 1-1.2 (100-130%)

- temps 220-250 (mfg rec is 235-250)

- 0.4 and 0.6 nozzle

- Cura and PrusaSlicer

Direct drive (Biqu H2 V2s) on a well-tuned Ender 3 (no issues with ABS, PETG, even nylon). Part fan off. Printing on PP tape (no adhesion issue).

I can get halfway decent looking print with 250C and a Flow rate of ~140% but it eventually jams anyway. Lower temps give super inconsistent extrusion, nozzle spitting chunks intermittently.

At my wits' end. Any more tips? I don't have any other TPU ATM, may be just shitty filament? It's a cheapo polish F3D Filament TPU 93A. Thanks!